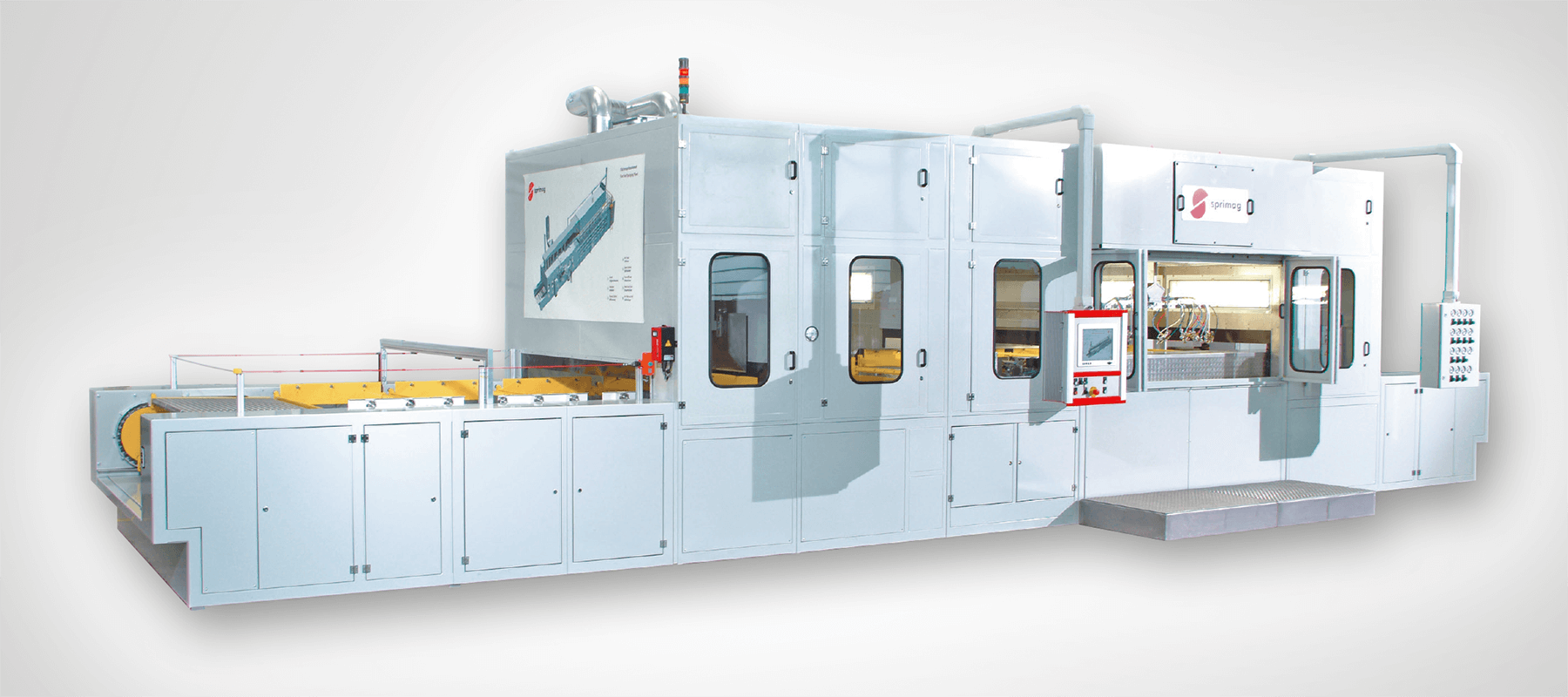

With the Sprimag Flat Bed Coating Machine flat parts may be coated in a single machine cycle. It is particularly suitable for plastic parts that must be coated precisely and in large quantity. Examples include: interior automotive parts, faceplates, pushbuttons, keyboards, appliance parts, furniture handles and many more.

High Transport Speed with Low Space Requirement

The standard pallet dimension of the Flat Bed Coating Machine is 2,400 x 800mm. Larger parts (e. g. photovoltaic panels) can be transferred on a conveyor belt without pallets. Reduced space requirements can be achieved by utilizing a multi-level dryer. Several spray guns mounted on a reciprocating axis allow high conveying speeds through the unit while maintaining a uniform coating.

- High productivity, especially with respect to the area coated

- Depending on the application various conveying technologies may be employed

- Step-less variation of conveying and axis speeds

- Stand-alone unit or integrated system

- High temperature stability provided by horizontal airflow dryers

- Over-spray extraction, wet or dry

- Spray guns can be easily exchanged, quick-change system

- Load and unload of parts at the same position

OPTIONS

- Pretreatment such as CO2, ionization, flame activation or plasma

- Convection, infrared, UV or induction dryers

- Multiple spray stations in a single unit

- Cleaning station with rotary brushes for the underside of the carrier frames

- Sprimag 2K-/3K-paint supply system, completely integrated in the central control system

- Waste disposal system (sludge press, centrifugal separator)