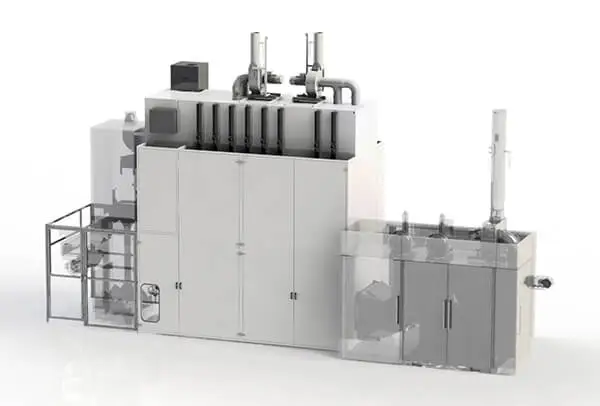

- Compact machine design

- Machinery speed up to 180 cans per minute

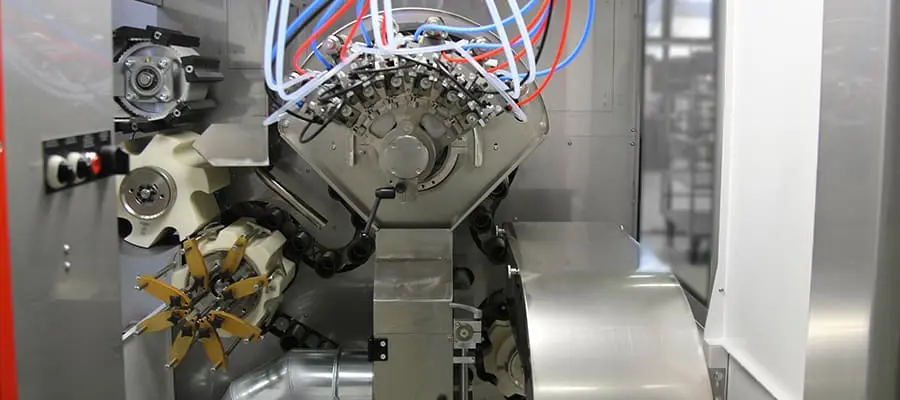

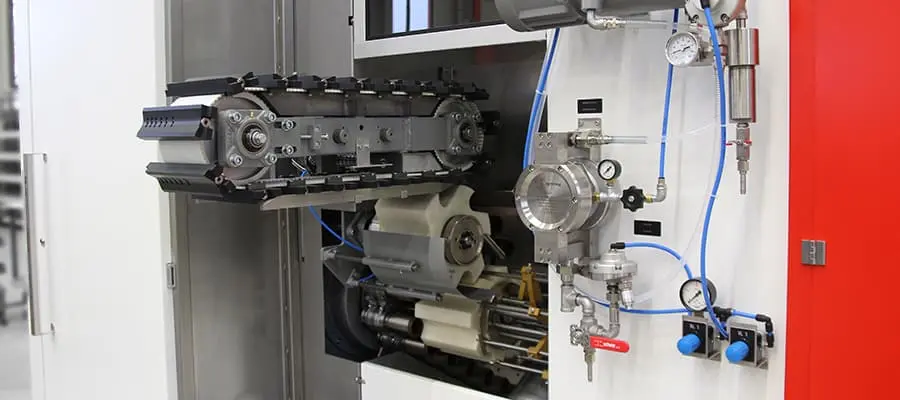

- Triple coating on 6 spray guns

- Separate servo drives for stroke and transport movement

- Proven quick-change system for size parts, compatible with HIL-64, HIL-70, HIL-94

- Automatic part ejection during production process

- Machine dimensions adjusted to integrate in older production lines

- Manufactured in accordance with the ATEX regulations

OPTIONS

- Additional lacquer supply

- Cleaning device for spray gun extensions

- Energy optimizing system and vacuum control

- Second spray arm with full spraying equipment assembly

- Can bottom suction device

- RFID-access verification system to organize access authorizations

- Division of spray gun groups into separately controlled circuits

- Flexible infeed concepts

TECHNICAL DATA

- Product range: Aerosol cans and beverage bottles

- Product diameter: Dmin 20 mm, Dmax 66 mm

- Trimmed can height: Lmin 70 mm, Lmax 270 mm

- Production speed: up to 180 cpm

- Spray guns/Spray process: 6/3 times or 4/2 times

Internal drier for cans DIT

- 1-, 2- or 3-row transport chain with baskets

- Reduced wearout of the transport chain and the chain wheels by cardan-based drive system

- Chain tensioner with weight, electronically monitored

- Easy accessibility to the drier interior due to large doors

- Quadruple door lock

- Isolated doors with special door hinges for synchronized door closing

- Large outer doors with smooth surface on the oven‘s front and rear sides

- Quick and easy removal and reassembly of the shafts and chain wheels in case of service

With the next click you will load the video from YouTube. In this case, YouTube may set cookies which we have no influence on.

More information.

More information.